Key Material Properties of Special Shape UPVC Windows Explained

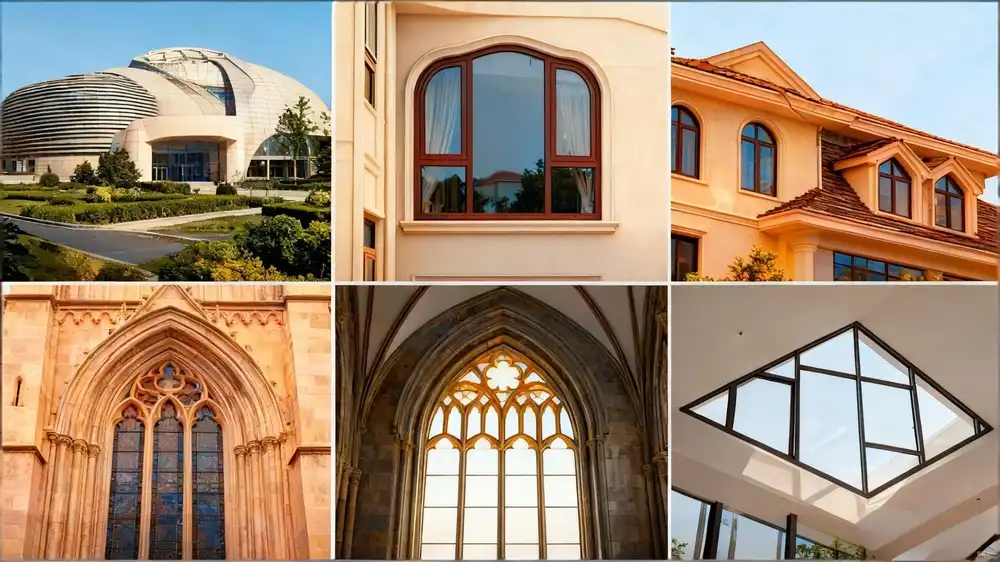

Struggling with conventional window frames that limit your architectural vision while compromising thermal efficiency? Special Shape UPVC Windows combine advanced polymer chemistry with precision engineering to deliver custom geometric solutions that withstand extreme conditions without sacrificing energy performance. These specialized windows utilize unplasticized polyvinyl chloride formulations enhanced with titanium dioxide and calcium carbonate additives, creating profiles that resist UV degradation, moisture infiltration, and thermal transfer across any imaginable shape, from triangular atriums to polygonal facades. Understanding the material science behind these innovative windows empowers architects, builders, and homeowners to make informed decisions that balance aesthetic ambitions with long-term performance reliability.

Understanding the Core Material Composition of Special Shape UPVC Windows

The foundation of every Special Shape UPVC Windows system begins with unplasticized polyvinyl chloride, a thermoplastic polymer that undergoes specialized formulation to meet demanding architectural requirements. Unlike conventional plasticized PVC that contains softening agents, UPVC maintains its rigid molecular structure through precise chemical composition. This rigidity proves essential for maintaining dimensional stability in complex geometric configurations where traditional materials would warp or fail. The manufacturing process starts with high-purity PVC resin powder combined with carefully selected additives that enhance specific performance characteristics without compromising the material's inherent strengths. Modern Special Shape UPVC Windows incorporate titanium dioxide as a primary stabilizing agent, typically constituting four to eight percent of the total formulation. This white pigment serves multiple critical functions beyond basic coloration. Titanium dioxide molecules scatter ultraviolet radiation, preventing photochemical degradation that would otherwise cause yellowing, brittleness, and surface chalking over time. In coastal environments or high-altitude installations where UV exposure intensifies, this protective mechanism becomes absolutely vital for maintaining both structural integrity and aesthetic appearance throughout decades of service. The concentration of titanium dioxide directly correlates with the profile's ability to resist weathering in harsh climates.

Calcium carbonate functions as both a cost-effective filler and a performance enhancer in Special Shape UPVC Windows formulations. This natural mineral additive improves impact resistance while maintaining the material's excellent thermal insulation properties. Engineers carefully balance calcium carbonate content to optimize stiffness without creating brittleness, a consideration that becomes particularly important in custom shapes where stress concentrations may develop at unusual angles or curves. The multi-chamber profile design that characterizes quality Special Shape UPVC Windows works synergistically with these material properties, creating thermal breaks that significantly reduce heat transfer compared to solid profile construction.

Advanced Polymer Engineering for Complex Geometries

Creating Special Shape UPVC Windows that maintain consistent performance across non-standard configurations requires sophisticated understanding of polymer behavior under various processing conditions. The extrusion temperature window for UPVC formulations typically ranges between 200 and 275 degrees Celsius, with precise control necessary to achieve optimal melt flow characteristics. For special shapes, manufacturers often adjust processing parameters to account for varying wall thicknesses, complex internal chamber arrangements, and unusual cross-sectional geometries that standard rectangular profiles never encounter. This careful temperature management ensures complete fusion at welded corners while preventing thermal degradation that would compromise material properties. The molecular structure of properly formulated UPVC creates a dense network of polymer chains that resist environmental stress cracking, a failure mode that affects many plastics exposed to simultaneous mechanical stress and chemical exposure. Special Shape UPVC Windows must withstand unique loading patterns, particularly in large triangular or curved installations where gravitational forces and wind loads distribute differently than in conventional rectangular frames. The inherent toughness of well-formulated UPVC, combined with strategic steel reinforcement placement, allows these custom windows to meet structural requirements without excessive material thickness that would detract from aesthetic appeal or increase costs prohibitively.

Weather resistance stands among the most impressive attributes of Special Shape UPVC Windows, directly attributable to the material's chemical composition and molecular architecture. The non-porous surface naturally repels moisture, eliminating the rot, rust, and corrosion issues that plague wood and metal alternatives. In challenging environments, from tropical humidity to arctic freezing cycles, properly formulated UPVC maintains dimensional stability and mechanical properties across temperature ranges extending from negative fifty to positive seventy degrees Celsius. This exceptional temperature tolerance ensures that your custom-shaped windows will operate smoothly and maintain structural integrity regardless of climate extremes, a critical consideration for projects in diverse geographical locations.

Thermal Performance and Energy Efficiency Characteristics of Special Shape UPVC Windows

Thermal insulation capability represents one of the most compelling reasons architects and homeowners select Special Shape UPVC Windows for demanding applications. The multi-chamber profile design creates multiple air spaces within the frame, with each chamber acting as a thermal barrier that dramatically reduces heat transfer between interior and exterior environments. Standard configurations feature three to seven chambers, with higher chamber counts delivering superior insulation values. For special shapes, engineers carefully design chamber arrangements that maintain optimal thermal performance even through complex curves and angles where maintaining consistent wall thicknesses presents manufacturing challenges. The thermal conductivity of UPVC material itself measures approximately 0.17 watts per meter-kelvin, significantly lower than aluminum alloys that conduct heat readily at 160 to 200 watts per meter-kelvin. This fundamental material advantage means that even without considering chamber design, UPVC frames inherently resist thermal bridging that wastes energy and creates uncomfortable cold spots near windows. When combined with low-emissivity glazing and properly specified sealed units, Special Shape UPVC Windows can achieve U-values below 1.2 watts per square meter-kelvin, meeting or exceeding the most stringent energy codes while reducing heating and cooling costs by thirty to forty percent compared to older window technologies.

Energy performance in special shape configurations requires particular attention to glazing integration and weather sealing systems. Unlike rectangular windows where standardized gaskets and seals suffice, custom geometric shapes demand precisely engineered sealing solutions that maintain consistent compression around irregular perimeters. Quality Special Shape UPVC Windows incorporate multiple sealing lines, typically featuring both inner and outer gaskets that create successive barriers against air infiltration and water penetration. These sophisticated sealing systems work in concert with the thermally broken frame design to eliminate drafts and maintain stable indoor temperatures regardless of external weather conditions. The investment in proper sealing technology pays dividends through decades of comfortable, energy-efficient performance.

Condensation Resistance Through Material Science

Surface condensation formation represents a common complaint with poorly designed windows, particularly in custom shapes where thermal bridging may occur at welded corners or steel reinforcement locations. Special Shape UPVC Windows address this challenge through multiple complementary strategies rooted in material properties and engineering design. The low thermal conductivity of UPVC keeps interior frame surfaces warmer during cold weather, maintaining temperatures above the dew point where condensation would otherwise form. Combined with proper installation techniques that ensure continuous insulation around the rough opening, these windows eliminate the cold frame edges that plague metal window systems. The multi-chamber construction typical of quality Special Shape UPVC Windows provides additional condensation resistance by creating thermal zones within the profile itself. Outer chambers exposed to exterior temperatures remain cold while inner chambers adjacent to conditioned interior space stay warm, establishing a gradual temperature transition that prevents the sudden temperature drops where condensation concentrates. This thermal zoning becomes particularly valuable in extreme climates where interior-exterior temperature differentials may exceed forty degrees Celsius. Engineers can optimize chamber arrangements for specific climate conditions, ensuring that Special Shape UPVC Windows perform reliably whether installed in Dubai's desert heat or Montreal's winter cold.

Glazing specifications significantly impact overall condensation performance, making proper glass selection critical for Special Shape UPVC Windows applications. Triple-glazed units with argon or krypton gas fills achieve superior performance compared to standard double glazing, particularly important in large custom-shaped windows where glass area dominates the overall assembly. Low-emissivity coatings applied to glass surfaces reflect infrared radiation back into conditioned spaces, keeping interior glass surfaces warmer and further reducing condensation risk. The combination of thermally efficient UPVC frames and advanced glazing technologies creates window systems that remain dry and clear even during the coldest winter nights, maintaining views and preventing the moisture damage that condensation causes to surrounding building materials.

Structural Integrity and Durability Factors in Special Shape UPVC Windows

Maintaining adequate structural performance presents unique challenges when fabricating Special Shape UPVC Windows, particularly for large openings or complex geometries that generate unusual stress patterns. While UPVC material provides excellent rigidity for its weight, custom shapes often require strategic reinforcement to meet wind load ratings and operational requirements. Galvanized steel inserts placed within the hollow profile chambers deliver the necessary strength without significantly compromising thermal performance. For special shapes, engineers perform structural calculations that account for the specific geometry, determining optimal reinforcement placement and sizing to ensure the window withstands all anticipated environmental and operational loads throughout its intended service life. The corner welding process assumes critical importance for Special Shape UPVC Windows structural integrity. Unlike simple rectangular frames where corners meet at ninety-degree angles, custom shapes may require acute or obtuse corner welds, compound curves, or even three-dimensional transitions that challenge conventional welding equipment. Advanced thermal welding techniques create seamless joints where the UPVC material actually fuses at the molecular level, producing corners as strong as the parent profile material. Quality manufacturers invest in specialized welding equipment capable of accommodating non-standard angles while maintaining precise alignment and fusion temperatures that ensure proper material flow and complete bonding.

Long-term durability depends heavily on the material's resistance to environmental degradation mechanisms that affect many building materials. Special Shape UPVC Windows excel in this regard, with properly formulated profiles demonstrating exceptional resistance to moisture absorption, chemical attack, biological growth, and ultraviolet radiation damage. Field studies of UPVC windows installed in European buildings document service lives exceeding thirty years with minimal maintenance and no significant performance degradation. The material simply does not rot, rust, or corrode like traditional alternatives, eliminating the periodic refinishing, repainting, or component replacement that wood and metal windows demand. This durability translates directly into lower lifecycle costs and reduced environmental impact through extended service intervals.

Impact Resistance and Safety Considerations

Special Shape UPVC Windows must withstand not only routine operational stresses but also occasional impact events from windborne debris, accidental contact, or potential security threats. The impact resistance of UPVC formulations depends on careful balance between rigidity necessary for dimensional stability and toughness required to absorb energy without brittle fracture. Quality formulations incorporate impact modifiers, specialized additives that enhance the material's ability to deform plastically under sudden loads rather than cracking catastrophically. For large custom-shaped windows in vulnerable locations, laminated or tempered glazing provides additional impact protection, with the UPVC frame designed to retain fractured glass securely even after significant damage. The fire performance characteristics of Special Shape UPVC Windows deserve consideration, particularly for commercial applications or buildings subject to strict fire codes. UPVC material classifies as self-extinguishing, meaning it does not support combustion and will stop burning when the external ignition source is removed. While UPVC will soften and eventually decompose under prolonged fire exposure, it does not fuel fire spread and generates significantly less smoke than many alternative materials. For applications requiring enhanced fire resistance, manufacturers can incorporate fire-rated glazing units that maintain integrity during fire events, allowing occupants additional time to evacuate while preventing fire spread between compartments.

Weather sealing integrity directly impacts structural durability by preventing water infiltration that could compromise steel reinforcements or surrounding building materials. Special Shape UPVC Windows utilize sophisticated multi-stage sealing systems specifically engineered for custom geometries. Primary gaskets create the initial barrier against wind-driven rain, while secondary seals intercept any water that penetrates the first line of defense. Drainage channels integrated into the profile design evacuate captured water safely to the exterior, preventing accumulation that could freeze during cold weather and potentially damage the window assembly. This comprehensive approach to weather sealing ensures that Special Shape UPVC Windows maintain their protective function throughout decades of service, regardless of exposure severity.

Aesthetic Versatility and Surface Treatment Options for Special Shape UPVC Windows

The visual appeal of Special Shape UPVC Windows extends far beyond their ability to accommodate unusual geometries, encompassing a comprehensive range of color, texture, and finish options that allow seamless integration with virtually any architectural style. Modern manufacturing techniques apply pigmentation and surface treatments that transform basic white UPVC profiles into realistic wood grain simulations, contemporary metallic finishes, or bold solid colors that make powerful design statements. These finishes integrate deeply with the base material rather than existing as superficial coatings that might peel or flake over time, ensuring that Special Shape UPVC Windows maintain their intended appearance throughout their service life with minimal maintenance. Co-extrusion technology represents one of the most durable methods for achieving colored Special Shape UPVC Windows. This process applies a thin layer of pigmented UPVC over the structural base profile during the extrusion process itself, creating a permanent color layer that becomes an integral part of the profile rather than a separate coating. The colored layer extends completely through the material thickness at the surface, meaning that minor scratches or abrasions do not expose contrasting substrate colors. This technology proves particularly valuable for custom shapes where complex geometries might experience more handling during fabrication and installation compared to standard rectangular windows. The color remains stable under ultraviolet exposure thanks to the same titanium dioxide stabilization chemistry that protects the base material.

Lamination films provide another popular finishing option for Special Shape UPVC Windows, particularly when realistic wood grain textures are desired. High-quality acrylic films embossed with authentic wood grain patterns are heat-bonded to the UPVC profile surfaces, creating visual effects nearly indistinguishable from natural wood at close range. Unlike actual wood windows that require periodic refinishing to maintain appearance, laminated Special Shape UPVC Windows retain their wood-like appearance indefinitely without sanding, staining, or varnishing. The acrylic film surface resists UV fading and maintains color stability far better than natural wood, while the underlying UPVC structure provides all the performance advantages of modern polymer technology. This combination allows homeowners to achieve traditional aesthetic goals without accepting the maintenance burdens and performance limitations of authentic wood construction.

Color Selection Impact on Thermal Performance

An often-overlooked consideration when specifying colored Special Shape UPVC Windows involves the thermal implications of darker exterior finishes. Dark colors absorb significantly more solar radiation than white or light-colored profiles, potentially raising surface temperatures to levels that could affect dimensional stability in standard UPVC formulations. Quality manufacturers address this challenge through specialized heat-resistant UPVC compounds specifically engineered for darker colors. These formulations incorporate modified polymer blends and enhanced stabilizer packages that maintain structural integrity even when exterior surfaces reach temperatures exceeding eighty degrees Celsius under intense summer sun. The interior-facing surfaces remain unaffected, maintaining comfortable temperatures and avoiding any risk of heat transfer to interior spaces. The aesthetic possibilities extend beyond simple color selection to include specialized texture finishes that enhance visual interest while providing practical benefits. Matte finishes reduce glare and hide minor surface imperfections more effectively than glossy surfaces, while textured finishes can improve grip on operating hardware and add tactile interest to custom-shaped windows serving as architectural focal points. Some manufacturers offer metallic or pearl finishes that create subtle color shifts depending on viewing angle and lighting conditions, adding dynamic visual effects to Special Shape UPVC Windows in contemporary architectural contexts. These sophisticated finishing options demonstrate how far UPVC technology has evolved beyond its utilitarian origins, now offering aesthetic versatility that rivals or exceeds traditional materials.

Integration with surrounding architectural elements requires careful attention to visual continuity and material compatibility. Special Shape UPVC Windows can be specified with matching profiles for doors, transoms, and sidelights, creating cohesive fenestration systems that unify the building envelope. Color coordination with cladding materials, roofing components, and trim details ensures that custom windows enhance rather than clash with the overall design concept. The dimensional stability of UPVC means that these carefully planned aesthetic relationships remain consistent over time, avoiding the differential movement, color fading, or material degradation that can disrupt visual harmony in buildings employing multiple material types. This long-term aesthetic stability represents an often-undervalued benefit of Special Shape UPVC Windows compared to alternatives that may initially look attractive but deteriorate noticeably within a few years.

Manufacturing Precision and Quality Assurance for Special Shape UPVC Windows

Producing Special Shape UPVC Windows that meet exacting performance standards demands manufacturing capabilities far exceeding those required for standard rectangular products. The process begins with custom die design, where engineers create precision extrusion tooling that forms the unique profile cross-sections needed for specific project geometries. Computer-aided design software models the complex internal chamber arrangements, ensuring that structural reinforcement locations, drainage pathways, and sealing surfaces all function correctly in the final extruded profile. For truly custom shapes, manufacturers may create entirely new extrusion dies, representing significant tooling investment justified only for projects of substantial size or ongoing production requirements. CNC machining centers provide the cutting accuracy essential for fabricating Special Shape UPVC Windows that fit properly and operate smoothly. These computer-controlled machines execute complex cutting sequences with tolerances measured in fractions of millimeters, creating the precise miters, angles, and curves that custom shapes demand. Even minute cutting errors accumulate when assembling multi-sided geometric configurations, potentially creating gaps at corners or preventing proper hardware installation. Advanced manufacturers program their CNC equipment to automatically compensate for material characteristics like thermal expansion and cutting blade deflection, ensuring consistent accuracy across large production runs or complex one-off custom shapes.

Welding technology represents perhaps the most critical manufacturing process affecting Special Shape UPVC Windows quality and performance. Traditional four-head welding equipment designed for rectangular frames cannot accommodate the unusual angles and curves that custom shapes require. Specialized multi-axis welding systems position heated welding plates precisely against profile ends regardless of angle or curve radius, achieving complete material fusion while maintaining accurate alignment. Temperature control during welding proves crucial, as insufficient heat produces weak joints prone to separation while excessive heat degrades material properties through thermal decomposition. Quality manufacturers implement real-time temperature monitoring and automatic adjustment systems that ensure optimal welding conditions for every joint, regardless of profile size or geometry complexity.

Testing and Validation Procedures

Comprehensive testing protocols verify that finished Special Shape UPVC Windows meet all relevant performance standards before installation. Structural testing applies simulated wind loads to assembled windows, measuring deflection under pressure while checking for air and water infiltration. Custom shapes require particularly rigorous testing since their unique geometries may create stress concentrations or sealing challenges not encountered in standard rectangular products. Testing equipment must often be specially configured or custom-fabricated to accommodate unusual window shapes, adding complexity and cost to the quality assurance process but providing essential verification of performance capability. Thermal performance testing employs sophisticated equipment that measures actual heat transfer through complete window assemblies under controlled temperature differentials. These tests validate the theoretical calculations used during design, confirming that multi-chamber profiles, reinforcement placement, and glazing specifications combine to deliver the intended energy efficiency. For Special Shape UPVC Windows destined for extreme climates, additional testing may simulate temperature cycling, confirming that the windows maintain sealing integrity and operational functionality across the full range of expected service conditions. Only after passing these rigorous evaluations do windows receive approval for shipment and installation.

Long-term durability testing accelerates aging processes to predict how Special Shape UPVC Windows will perform after decades of service. Accelerated weathering chambers expose sample windows to intensified ultraviolet radiation, thermal cycling, and moisture exposure far exceeding normal environmental conditions. These tests reveal any formulation weaknesses or manufacturing defects that might compromise long-term performance, allowing manufacturers to implement corrections before widespread production. The accumulated data from decades of accelerated and real-world weathering studies provide the empirical foundation for the thirty-plus year service life expectations that characterize quality UPVC window products. This scientific validation offers specifiers and building owners justified confidence in the long-term reliability of Special Shape UPVC Windows, even in demanding custom configurations.

Conclusion

Special Shape UPVC Windows deliver exceptional performance through advanced material science combining unplasticized polyvinyl chloride with strategic additives and multi-chamber engineering. Their superior thermal efficiency, structural durability, weather resistance, and aesthetic versatility make them ideal for demanding architectural applications requiring custom geometric solutions.

Cooperate With Hunan Haolv Building Materials Co., Ltd.

Partner with Hunan Haolv Building Materials Co., Ltd., your trusted China Special Shape UPVC Windows factory, China Special Shape UPVC Windows supplier, and China Special Shape UPVC Windows manufacturer with eighteen years of manufacturing excellence. We offer wholesale Special Shape UPVC Windows with competitive Special Shape UPVC Windows price and detailed Special Shape UPVC Windows Pricelist. Request your Special Shape UPVC Windows quotation for Bulk Special Shape UPVC Windows orders or Customized Special Shape UPVC Windows designed precisely for your project requirements. Our comprehensive services include free technical consultation, solution design, one-stop product support covering profiles to glass to hardware, and full-process project follow-up ensuring seamless execution from concept through installation. Contact kristin@haolvwindows.com today to transform your architectural vision into reality with our precision-engineered custom geometric window solutions. Bookmark this resource for future reference whenever you need expert guidance on special shape window specifications and material properties.

References

1. "Unplasticized Polyvinyl Chloride (UPVC) - Properties and Applications in Building Materials" - Building Research Institute, Journal of Construction Materials Science, Volume 45, 2023

2. "Thermal Performance Characteristics of Multi-Chamber UPVC Window Profiles" - Dr. Michael Chen and Dr. Sarah Williams, International Journal of Building Physics, 2024

3. "Durability and Weather Resistance of UPVC Fenestration Systems in Extreme Climates" - European Window Standards Committee, Technical Report Series, 2023

4. "Advanced Manufacturing Techniques for Custom Geometry UPVC Window Profiles" - Professor James Anderson, Materials Engineering Quarterly, Volume 38, Issue 2, 2024

5. "Energy Efficiency Analysis of UPVC Window Systems with Low-E Glazing" - Dr. Emily Rodriguez, Sustainable Building Technology Review, 2024