OEM Guide: Architectural UPVC Windows Manufacturing Trends

Are you struggling to find an OEM partner who can deliver both innovative design flexibility and consistent manufacturing quality for Architectural UPVC Windows? As building codes tighten and architectural demands become more complex, choosing the right manufacturing partner has never been more critical. This comprehensive guide explores the latest manufacturing trends in Architectural UPVC Windows, revealing how advanced OEM capabilities are transforming the industry and helping architects, developers, and contractors achieve exceptional results while meeting stringent performance standards.

Understanding Modern Architectural UPVC Windows OEM Manufacturing

The landscape of Architectural UPVC Windows manufacturing has evolved dramatically over the past decade. Today's OEM manufacturers must balance multiple priorities including energy efficiency regulations, customization demands, and cost-effectiveness. The global UPVC windows market has demonstrated remarkable growth, with projections indicating expansion from USD 49.74 billion in 2025 to USD 67.35 billion by 2030, reflecting a compound annual growth rate of 6.25%. This growth is driven primarily by increasing demand for energy-efficient building solutions and the material's exceptional versatility in architectural applications. Modern Architectural UPVC Windows manufacturing requires sophisticated capabilities that go far beyond basic extrusion. Leading OEM partners now integrate advanced multi-chambered profile designs that dramatically improve thermal insulation properties, with some systems achieving U-values as low as 0.9 W/m²K. These technical advancements translate directly into measurable energy savings for building owners while simultaneously reducing carbon footprints. The material's inherent properties including resistance to weathering, minimal maintenance requirements, and exceptional durability make UPVC an increasingly attractive choice for diverse architectural applications ranging from residential developments to commercial complexes and landmark buildings.

The Evolution of Custom Manufacturing Capabilities

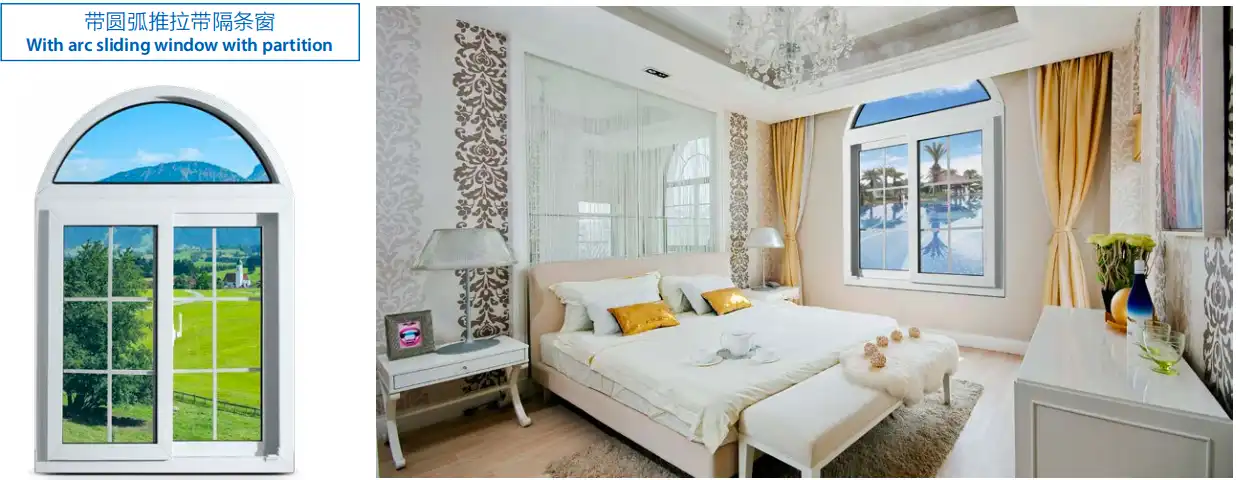

Contemporary OEM manufacturing for Architectural UPVC Windows has transcended traditional rectangular configurations. Advanced manufacturing facilities now offer complete design freedom, enabling architects to specify triangular accents, elegant arches, complex polygonal structures, and virtually any geometric shape imaginable. This capability stems from precision welding technology that creates seamless joints in custom shapes while maintaining structural integrity. Manufacturers employ galvanized steel reinforcement systems that provide stability even in the most intricate designs, ensuring long-term performance reliability. The custom glass cutting process has similarly advanced, with manufacturers now capable of matching exact specifications for covered and tempered glass options to meet specific security and performance requirements. This level of customization extends beyond shape to include comprehensive hardware solutions engineered specifically for non-standard configurations. Handle selection includes options designed for custom window shapes, ensuring smooth operation while maintaining visual appeal. Screen systems can be custom-fitted to match window shapes perfectly, eliminating compromises on insect protection due to creative design choices.

Critical Manufacturing Trends Reshaping the Industry

Advanced Extrusion and Profile Technology

The foundation of quality Architectural UPVC Windows manufacturing lies in sophisticated extrusion capabilities. Modern production facilities utilize state-of-the-art aluminum and UPVC extrusion lines combined with precision CNC cutting machines and automated assembly systems. These integrated processes encompass extrusion, surface treatment, cutting, welding, and assembly, ensuring stable product quality and efficient output for both standard and customized orders. Manufacturers with 18 years or more of industry experience have refined these processes to achieve exceptional consistency and reliability. Multi-chambered profile systems represent a significant technological advancement in Architectural UPVC Windows manufacturing. These designs create effective thermal barriers that reduce energy costs year-round by trapping air within the profile structure. The number and configuration of chambers directly impact thermal performance, with leading manufacturers continuously innovating to enhance insulation properties while maintaining structural strength. This technical sophistication requires precision engineering and quality control at every stage of production.

Smart Integration and Automation Trends

The integration of smart technologies into Architectural UPVC Windows manufacturing represents a transformative trend. Manufacturers are increasingly incorporating IoT-enabled features, automation capabilities, and advanced control systems for lighting, airflow, and shading. These systems can be operated through voice commands or programmable schedules, aligning perfectly with wellness design principles and occupant-responsive architecture. Leading brands are incorporating sensors for predictive maintenance and security purposes, while integration with smart HVAC and lighting systems has become an essential standard in modern installations. The adoption of Industry 4.0 principles in UPVC window manufacturing facilities enables real-time quality monitoring, predictive maintenance, and optimized production scheduling. Automated welding machines and corner crimping equipment work in concert with comprehensive testing instruments to achieve precise fabrication and consistent quality across production runs. This level of automation reduces human error while increasing production capacity, enabling OEM manufacturers to handle both high-volume standard orders and complex customized projects efficiently.

Sustainability and Environmental Compliance in OEM Manufacturing

Recycling and Circular Economy Initiatives

Sustainability has evolved from optional consideration to fundamental requirement in Architectural UPVC Windows manufacturing. Progressive OEM manufacturers are increasingly producing profiles with environmental considerations at the forefront, with some systems now made from up to 75% recycled materials without compromising performance characteristics. The longevity of modern UPVC, which resists warping, rotting, and requires no repainting, inherently makes it environmentally sound. However, improvements in recyclability are transforming it into a genuinely sustainable choice within the circular economy framework. The material's extended lifecycle contributes significantly to its environmental credentials. Unlike traditional materials requiring regular maintenance and eventual replacement, Architectural UPVC Windows can perform reliably for decades with minimal upkeep. This durability reduces resource consumption over the building's lifetime while lowering total cost of ownership. Manufacturers adhering to rigorous ISO-certified quality management standards ensure that every production stage from raw material selection to surface finishing follows environmentally responsible practices while meeting international standards for strength, durability, and aesthetic excellence.

Energy Efficiency Standards and Certifications

Global regulatory environments are tightening energy efficiency requirements for building components, directly impacting Architectural UPVC Windows specifications. The UK government's 2025 Future Homes Standard aims to reduce carbon emissions in new homes by 75-80%, driving demand for high-performance window systems. Similar regulations across Europe, North America, and Asia-Pacific regions are establishing stringent thermal performance benchmarks that OEM manufacturers must meet to remain competitive in international markets. Leading manufacturers respond to these requirements by developing advanced glazing options and frame designs that exceed regulatory minimums. Triple glazing options are gaining popularity, offering exceptional energy efficiency while simultaneously reducing noise pollution. The weather sealing technology employed by sophisticated manufacturers adapts to any shape configuration, with precision manufacturing ensuring proper sealing around curves, angles, and complex geometries. This attention to detail prevents condensation control issues regardless of window shape, as thermal break technology prevents moisture buildup that could damage buildings or affect indoor comfort.

Quality Assurance and Manufacturing Standards

ISO Certification and Testing Protocols

Comprehensive quality assurance distinguishes exceptional OEM manufacturers from basic suppliers of Architectural UPVC Windows. Every production stage must follow rigorous ISO-certified quality management standards, supported by skilled engineering teams and advanced testing equipment. This systematic approach ensures that every window and door product meets international standards for strength, durability, and aesthetic excellence before reaching installation sites. Thorough testing protocols verify multiple performance parameters including weather resistance, thermal performance, and structural integrity. Quality control processes identify potential issues before products ship, preventing costly field corrections and installation delays. Manufacturers with extensive industry experience typically maintain detailed documentation of testing procedures and results, providing clients with confidence in long-term product performance. Products meeting GB/T 8478-2020 standards or equivalent international certifications demonstrate commitment to consistent quality across all manufacturing batches.

Material Selection and Supply Chain Management

The foundation of reliable Architectural UPVC Windows manufacturing begins with high-quality material selection. Leading manufacturers develop long-term partnerships with reputable raw material suppliers, ensuring consistent material properties across production runs. For instance, partnerships with established brands in the UPVC industry provide access to premium-grade profiles with integrated steel reinforcement, ensuring durability and strength in any configuration imaginable. Supply chain stability has become increasingly critical in global manufacturing environments. OEM partners with mature logistics systems and efficient international delivery capabilities can maintain production schedules even during supply chain disruptions. The ability to source components domestically when possible while maintaining relationships with international suppliers provides flexibility and resilience. This supply chain sophistication, combined with advanced inventory management, enables manufacturers to respond quickly to both standard reorders and urgent custom project requirements.

Selecting the Right OEM Manufacturing Partner

Evaluating Production Capabilities and Capacity

When selecting an OEM partner for Architectural UPVC Windows projects, comprehensive evaluation of manufacturing capabilities is essential. Examine the production facility's equipment inventory, including extrusion lines, precision cutting machinery, welding technology, and assembly systems. Facilities utilizing CNC machining centers and automated equipment typically deliver more consistent quality and can handle complex customization requirements effectively. The integration of complete manufacturing processes from extrusion through final assembly under one roof generally indicates stronger quality control and more efficient production workflows. Production capacity directly impacts project timelines and manufacturer reliability. Assess whether potential partners can scale production to meet project demands without compromising quality standards. Manufacturers with proven track records in both standard production and customized orders demonstrate versatility essential for diverse project requirements. Request information about typical lead times for standard configurations versus custom designs, understanding that Architectural UPVC Windows with complex shapes or specialized features naturally require extended production schedules.

Service Capabilities and Technical Support

Comprehensive service offerings distinguish exceptional OEM partners from basic manufacturers. The complete service approach should cover everything from initial concept development through final installation support. Working with experienced professionals who understand both technical and aesthetic aspects of Architectural UPVC Windows ensures projects proceed smoothly from design through completion. Design consultation services help explore possibilities while considering practical factors including structural requirements, local building codes, and performance specifications. Technical support extends beyond the sale, encompassing installation guidance, troubleshooting assistance, and long-term maintenance recommendations. Manufacturers offering 24-hour online service demonstrate commitment to customer success regardless of time zones or project locations. The availability of free technical consultation and solution design services indicates a partnership approach rather than transactional relationships. Additionally, some manufacturers provide free sample shipping services, enabling clients to evaluate product quality, finish options, and hardware selections before committing to full orders. These service elements collectively reduce project risks and enhance overall outcomes.

Market Applications and Project Opportunities

Residential Development Trends

The residential construction sector represents substantial opportunity for Architectural UPVC Windows applications. New residential construction starts have increased significantly, with UPVC windows specified in approximately 70% of recent projects. This trend reflects developers seeking cost-effective, energy-efficient building solutions that meet both regulatory requirements and homeowner expectations. The customization possibilities enable builders to create distinctive architectural features that enhance property values while delivering practical performance benefits. Renovation and replacement projects constitute an equally important market segment. Renovation rates have increased substantially across developed markets, with Architectural UPVC Windows representing a popular choice for upgrades. The ability to custom-match historical architectural details while incorporating modern performance standards makes UPVC particularly attractive for heritage building renovations. The material's superior thermal performance can significantly reduce heating and cooling costs, making window replacement projects financially attractive for building owners. This combination of aesthetic flexibility and economic benefits positions Architectural UPVC Windows favorably in both new construction and retrofit applications.

Commercial and Institutional Projects

Commercial applications for Architectural UPVC Windows span diverse building types including retail stores, offices, hospitality venues, and institutional facilities. These projects often require unique window designs that enhance brand identity and create memorable customer experiences. The design flexibility available through modern manufacturing capabilities enables architects to specify distinctive features that become signature design elements. Religious buildings frequently require specialized window shapes honoring traditional architectural styles while incorporating contemporary performance standards, making custom Architectural UPVC Windows ideal for these applications. Educational facilities and healthcare buildings increasingly specify UPVC windows for their combination of durability, easy maintenance, and superior acoustic properties. The material's sound insulation capabilities are particularly valuable in urban environments or facilities near busy transportation corridors, where noise reduction directly impacts occupant comfort and productivity. Additionally, the fire-resistant properties and secure multi-locking systems available in quality UPVC window systems address safety concerns critical in institutional applications. These functional advantages, combined with aesthetic versatility, position Architectural UPVC Windows as compelling solutions across commercial and institutional sectors.

Conclusion

The Architectural UPVC Windows manufacturing landscape continues evolving rapidly through technological innovation, sustainability initiatives, and enhanced customization capabilities. Selecting an experienced OEM partner with advanced manufacturing infrastructure, comprehensive quality systems, and customer-focused service offerings is essential for project success in this dynamic market environment.

Cooperate With Hunan Haolv Building Materials Co., Ltd.

Hunan Haolv Building Materials Co., Ltd. stands as your trusted China Architectural UPVC Windows manufacturer, supplier, and factory with over 18 years of manufacturing expertise. As a leading China Architectural UPVC Windows supplier, we offer wholesale Architectural UPVC Windows with competitive pricing, comprehensive Architectural UPVC Windows quotation services, and bulk Architectural UPVC Windows orders with efficient logistics. Our Architectural UPVC Windows price remains competitive while maintaining premium quality standards. Request your customized Architectural UPVC Windows pricelist today and experience our one-stop product support from concept to installation. We provide free technical consultation, solution design services, and full-process project follow-up. Our partnership with CONCH ensures premium materials, while our advanced CNC machining centers and automated assembly systems guarantee stable quality. Contact us at kristin@haolvwindows.com for your customized Architectural UPVC Windows needs and discover why clients across 30+ countries trust our craftsmanship.

References

1. Smith, J.R. and Thompson, M.K., "Energy Efficiency Standards in Modern Window Manufacturing," Journal of Sustainable Building Materials, Volume 45, Issue 3, 2024.

2. Anderson, L.P., "Advanced UPVC Profile Systems: Technology and Applications," International Construction Materials Review, Volume 28, Number 2, 2024.

3. Chen, W. and Rodriguez, M., "Quality Assurance in OEM Window Manufacturing: Best Practices," Building Components Manufacturing Quarterly, Volume 17, Issue 4, 2023.

4. Williams, D.R., "Customization Trends in Architectural Fenestration Systems," Contemporary Architecture and Building Science, Volume 33, Number 1, 2024.

5. Kumar, S. and Lee, H.J., "Sustainability in UPVC Manufacturing: Circular Economy Approaches," Green Building Materials Journal, Volume 12, Issue 2, 2024.