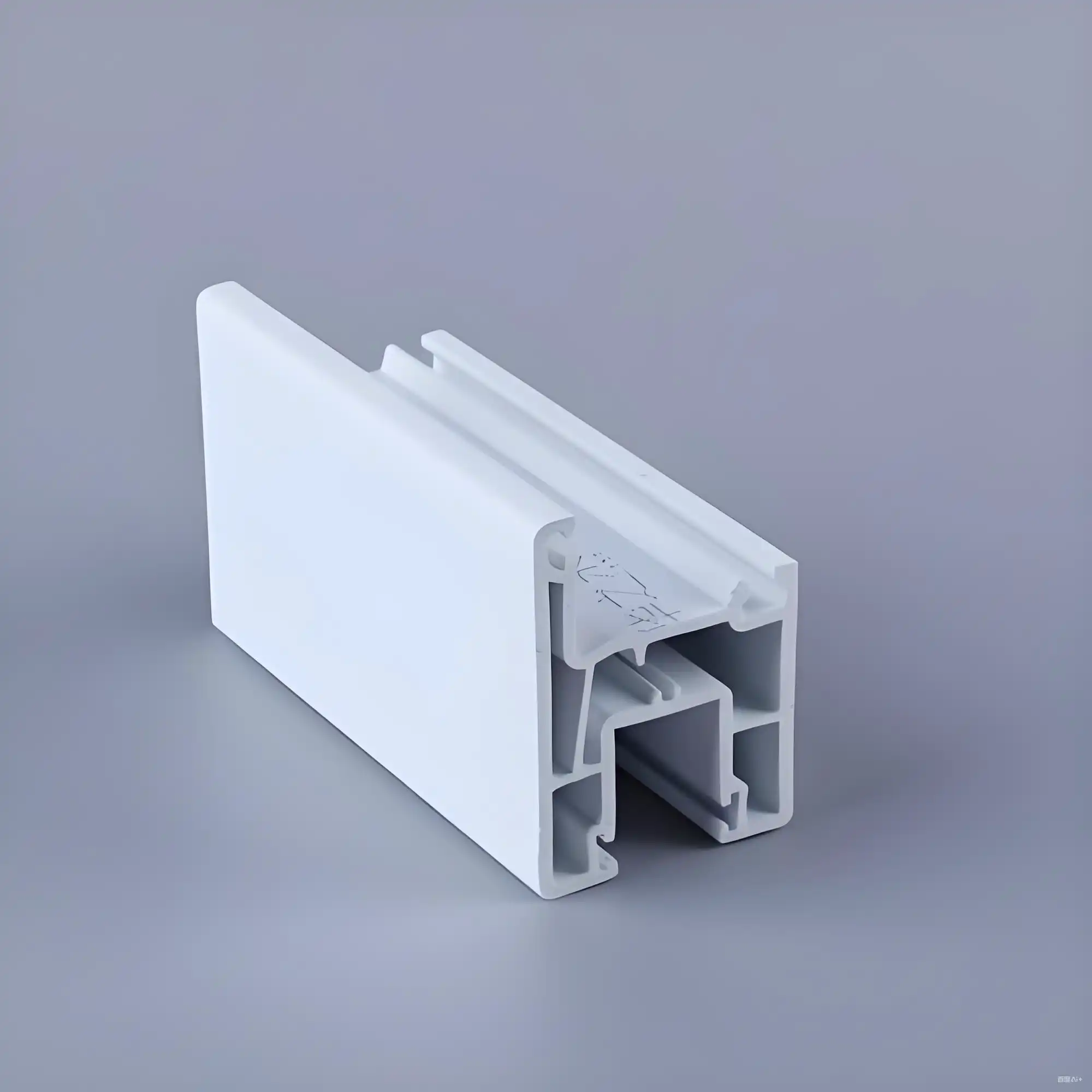

Working with a uPVC Profile Manufacturer Can Save You Costs!

Are you constantly battling high maintenance bills, skyrocketing energy costs, and frequent replacement expenses for your windows and doors? Many construction professionals and property developers face these challenges when using traditional building materials. Working directly with a uPVC profile manufacturer eliminates middleman markups, reduces material waste through customization, and delivers long-term savings through energy-efficient UPVC profiles that require minimal maintenance over decades of service.

Understanding Direct Manufacturer Advantages for UPVC Profiles

When you partner with a manufacturer specializing in UPVC profiles, you gain access to wholesale pricing structures that traditional retailers cannot match. Direct collaboration eliminates distribution channels, allowing you to purchase high-quality profiles at factory prices rather than marked-up retail costs. This direct relationship creates transparency in pricing, material selection, and production timelines that benefit your project budget from the initial quote through final installation. Manufacturing partners also provide technical expertise that helps you select the most cost-effective profile configurations for your specific applications, whether residential buildings, commercial complexes, or specialized projects like sunrooms. Beyond immediate purchase price advantages, working with experienced UPVC profiles manufacturers means accessing decades of material science knowledge and production optimization. These manufacturers understand how multi-chambered designs, reinforcement placement, and extrusion techniques impact both performance and cost. They can recommend profile specifications that balance your budget constraints with performance requirements, ensuring you don't overpay for unnecessary features while maintaining quality standards. This expertise becomes particularly valuable when scaling projects or entering new markets where local building codes and climate conditions require specific material properties.

Eliminating Middleman Costs and Markups

Traditional supply chains for building materials typically involve multiple intermediaries between the manufacturer and end user. Each distributor, wholesaler, and retailer adds their profit margin, inflating the final price you pay for UPVC profiles by 30-60% compared to factory direct pricing. By establishing a direct relationship with a China UPVC profiles manufacturer like Hunan Haolv Building Materials Co., Ltd., your purchasing power increases dramatically. You negotiate directly with the production source, accessing bulk UPVC profiles pricing that reflects actual manufacturing costs plus a single reasonable margin rather than compounded markups through multiple handlers. This direct purchasing model also accelerates your procurement timeline and improves inventory management. Instead of waiting for products to move through distribution networks, your orders move from production lines to shipping containers destined for your project sites. The manufacturer's logistics team coordinates delivery schedules aligned with your construction timelines, reducing storage costs and minimizing the capital tied up in inventory. When urgent needs arise or project specifications change, direct communication with the manufacturing team facilitates rapid responses that would be impossible through traditional supply chains with their multiple approval layers and communication delays.

Customization Without Premium Pricing

Standard UPVC profiles available through retail channels often force compromise between available options and your actual project requirements. Manufacturers working directly with clients offer customized UPVC profiles tailored to specific dimensional needs, aesthetic preferences, and performance specifications without the extreme premium pricing typically associated with custom orders through distributors. This customization extends beyond basic dimensions to include chamber configurations optimized for your climate zone, reinforcement patterns matched to your wind load requirements, and color options aligned with your architectural vision. The ability to customize profiles directly with manufacturers also reduces material waste on your job sites. When profiles arrive cut to exact specifications rather than standard lengths requiring field modifications, you eliminate the scrap material that represents both wasted money and disposal costs. Custom color matching and surface finishes applied during manufacturing eliminate the need for post-production treatments that add labor costs and extend project timelines. These seemingly small efficiencies compound across large projects, translating to substantial savings that directly improve your profit margins while maintaining the quality expectations of your clients.

Long-Term Cost Savings Through Quality UPVC Profiles

The true value of working with reputable UPVC profiles suppliers extends far beyond initial purchase prices. Quality profiles manufactured with lead-free materials, optimal multi-chamber designs, and precision-engineered tolerances deliver decades of maintenance-free performance. Unlike wood frames that require periodic painting, sealing, and rot prevention treatments, or aluminum frames prone to condensation and thermal bridging problems, properly manufactured UPVC profiles maintain their structural integrity and appearance with nothing more than occasional soap and water cleaning. This dramatic reduction in maintenance requirements translates to thousands of dollars saved over the typical 25-30 year lifespan of these installations. Energy efficiency represents another major source of long-term savings when using high-quality UPVC profiles from established manufacturers. The multi-chambered construction inherent to well-designed profiles creates air pockets that dramatically reduce thermal transfer between interior and exterior environments. Buildings equipped with quality UPVC windows and doors maintain more stable interior temperatures, reducing HVAC system runtime and extending equipment lifespan while cutting monthly energy bills by 15-30% compared to single-glazed or poorly insulated alternatives. These energy savings accumulate year after year, often exceeding the initial material cost difference within five to seven years of installation.

Durability Equals Reduced Replacement Frequency

Construction materials represent significant capital investments, and premature failure forces unexpected replacement costs that devastate project budgets and property maintenance reserves. UPVC profiles manufactured according to international quality standards demonstrate exceptional resistance to environmental stressors that degrade alternative materials. They neither rust like steel, corrode like aluminum in coastal environments, nor rot like wood in humid climates. This inherent material stability means windows and doors fabricated from quality profiles maintain structural integrity and operational smoothness for decades, eliminating the replacement cycles that plague buildings using inferior materials. The galvanized steel reinforcement integrated into quality UPVC profiles provides structural rigidity that prevents warping, sagging, and operational failures common in unreinforced or poorly reinforced alternatives. This reinforcement system, combined with precision manufacturing tolerances, ensures that door and window assemblies maintain proper alignment throughout their service life. Hardware continues operating smoothly, seals maintain effective contact, and the aesthetic appearance remains consistent rather than deteriorating into the shabby appearance that forces premature replacement for cosmetic rather than functional reasons. Property owners and facility managers appreciate this longevity, often becoming repeat customers who recognize the true lifetime value proposition.

Energy Efficiency Translating to Lower Operating Costs

Modern building codes increasingly emphasize energy performance, and properties equipped with efficient UPVC profiles meet these standards while delivering measurable operating cost reductions. The thermal insulation properties of multi-chambered profiles minimize heat loss during winter and heat gain during summer, reducing the workload on heating and cooling systems. This efficiency extends equipment lifespan by reducing runtime hours and minimizes peak demand charges in commercial applications where utility rates escalate during high-consumption periods. The acoustic insulation properties of quality UPVC profiles also contribute to occupant comfort and productivity, creating value that extends beyond simple energy cost calculations. For developers and property managers working in hot climates, the UV-resistant titanium dioxide additives used in quality UPVC profiles prevent degradation and color fading that plague cheaper alternatives. This UV stability maintains both functional performance and aesthetic appearance, eliminating the need for protective treatments or premature replacement due to sun damage. In cold climates, the low thermal conductivity of UPVC profiles eliminates the condensation problems common with aluminum frames, preventing moisture damage to surrounding building materials and avoiding the mold growth that creates health hazards and expensive remediation requirements.

Strategic Advantages of Manufacturer Partnerships

Establishing ongoing relationships with China UPVC profiles suppliers creates strategic advantages extending far beyond individual project savings. Manufacturers value long-term partnerships and demonstrate this commitment through priority production scheduling, flexible payment terms, and technical support that helps you win competitive bids and execute projects more efficiently. Access to manufacturer engineering teams provides design assistance that optimizes product selection for specific applications, ensuring you specify the most cost-effective solutions while meeting all performance requirements. This collaborative approach transforms your supplier relationship from transactional commodity purchasing into a strategic partnership that enhances your competitive position. Leading manufacturers also invest continuously in research and development, improving production efficiency and product performance in ways that benefit their partners. As an established customer, you gain early access to innovative profile designs, improved material formulations, and manufacturing techniques that reduce costs or enhance performance. This inside track on industry developments positions you ahead of competitors still working through traditional distribution channels where new products arrive months or years after manufacturer introduction. The technical training and installation support provided by manufacturers committed to partner success also improves your team's capabilities, reducing installation time and minimizing costly errors that impact project profitability.

Reliable Supply Chain and Inventory Management

Construction projects operate on tight schedules where material delays cascade into expensive impacts on labor utilization, equipment rentals, and contract penalties. Working directly with UPVC profiles manufacturers provides supply chain visibility and reliability impossible through multi-tiered distribution networks. You communicate directly with production planning teams, receiving accurate lead time information and proactive updates about potential delays. This transparency enables better project planning and allows you to adjust schedules or secure alternative resources before problems impact critical path activities. Established manufacturers maintain appropriate inventory levels of standard profiles and raw materials, ensuring rapid response to your orders even during industry-wide demand surges that strain distribution networks. Their production capacity and material sourcing relationships provide security of supply that protects your projects from the material shortages that periodically disrupt construction markets. For larger projects or ongoing development programs, manufacturers often establish consignment inventory arrangements or vendor-managed inventory systems that ensure materials arrive exactly when needed without tying up your working capital in advance purchases. These sophisticated supply chain solutions demonstrate the strategic value of direct manufacturer relationships beyond simple purchase price advantages.

Technical Support and Installation Expertise

The complexity of modern building systems requires deep technical knowledge to achieve optimal performance and avoid costly installation errors. Manufacturers specializing in UPVC profiles maintain engineering teams who understand every aspect of their products, from material science fundamentals to optimal installation techniques for different applications and environmental conditions. This expertise becomes available to you through direct manufacturer relationships, providing specification guidance, installation training, and troubleshooting support that ensures successful project outcomes. When challenges arise during installation or performance questions emerge after occupancy, direct access to manufacturer technical support resolves issues quickly rather than filtering questions through distributor representatives with limited technical depth. Many manufacturers also provide installation certification programs that train your crews in best practices specific to their product lines. These training investments improve installation quality, reduce callback rates, and accelerate installation speed as crews become more familiar with optimal techniques. The manufacturer's commitment to proper installation protects both their reputation and your project success, creating aligned incentives that benefit everyone. Some manufacturers even provide on-site technical representatives for complex or high-visibility projects, ensuring that critical installations proceed smoothly and meet all performance expectations. This level of support simply doesn't exist when purchasing through traditional distribution channels focused primarily on product movement rather than application success.

Quality Assurance and Certification Benefits

Reputable UPVC profiles manufacturers maintain rigorous quality management systems certified to international standards like ISO 9001, demonstrating systematic approaches to production consistency and continuous improvement. These certification programs require regular third-party audits verifying that documented quality procedures are actually followed in daily operations. When you partner with certified manufacturers, you gain confidence that every profile meets specified standards regardless of production date or batch. This consistency eliminates the quality variability that creates expensive rework, delays, and customer satisfaction issues when inferior materials fail to perform as expected. Beyond management system certifications, quality manufacturers subject their UPVC profiles to extensive performance testing validating compliance with industry standards for structural strength, weather resistance, thermal performance, and durability. Test reports documenting these performance characteristics provide the evidence needed to satisfy building inspectors, meet project specifications, and demonstrate value to your clients. Some manufacturers even provide material test reports and certifications for each shipment, creating complete documentation trails that protect you from liability concerns and facilitate insurance compliance. This commitment to quality assurance and transparency distinguishes professional manufacturers from commodity suppliers focused solely on price competition.

Conclusion

Partnering directly with a professional UPVC profiles manufacturer delivers immediate cost savings through wholesale pricing while creating long-term value through superior product quality, reliable supply chains, and strategic support services that enhance your competitive capabilities throughout your business.

Cooperate With Hunan Haolv Building Materials Co., Ltd.

As a leading China UPVC profiles factory with over 18 years of manufacturing expertise, Hunan Haolv Building Materials Co., Ltd. specializes in delivering high-quality customized UPVC profiles backed by advanced production facilities and ISO-certified quality management. Our comprehensive services include free technical consultation, one-stop product support from frames to accessories, and 24-hour customer service ensuring your projects succeed. Request your wholesale UPVC profiles quotation or bulk UPVC profiles pricelist today, and discover how our customized UPVC profiles solutions, competitive UPVC profiles price, and proven reliability make us your ideal China UPVC profiles supplier and manufacturer. Contact us at kristin@haolvwindows.com for personalized assistance.

References

1. Construction Industry Research Board. (2023). "Life Cycle Cost Analysis of Building Materials." Journal of Construction Economics, Volume 45, Issue 3.

2. International Building Materials Association. (2024). "Energy Efficiency Standards for Window and Door Systems." Technical Report Series, Annual Edition.

3. Wang, J., Chen, L., & Liu, S. (2023). "Comparative Study of Thermal Performance in Modern Building Envelope Materials." Building Science Journal, Volume 38, Issue 2.

4. European Committee for Standardization. (2024). "Quality Assurance in UPVC Profile Manufacturing: Best Practices." CEN Technical Guide, Third Edition.

5. Zhang, M., Thompson, R., & Anderson, K. (2023). "Supply Chain Optimization in Construction Materials Procurement." International Journal of Construction Management, Volume 29, Issue 4.