Benefits of Reinforced UPVC Profiles in Extreme Weather Conditions

When storms approach, temperatures plummet to freezing levels, or scorching heat beats down on your building, are your windows and doors ready to withstand the assault? Many property owners discover too late that standard profiles buckle, warp, or fail when extreme weather strikes, leading to costly repairs, energy waste, and compromised safety. Reinforced UPVC Profiles offer a proven solution to these challenges, combining advanced engineering with durable materials to protect your investment through the harshest environmental conditions while maintaining thermal efficiency and structural integrity.

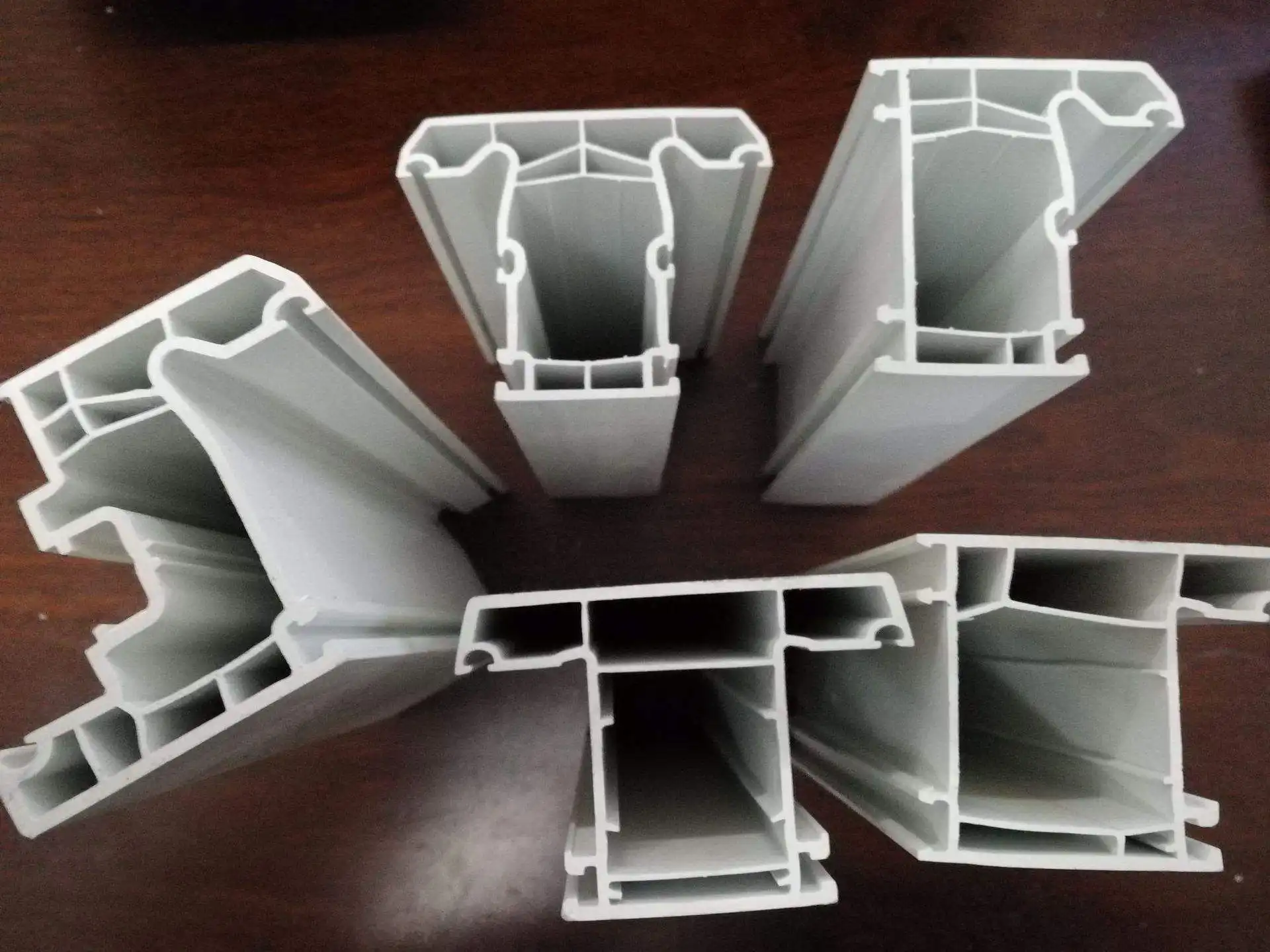

Understanding Reinforced UPVC Profiles and Their Construction

Reinforced UPVC Profiles represent a sophisticated engineering approach to window and door manufacturing that addresses the limitations of standard uPVC materials. These profiles integrate galvanized steel reinforcement within multi-chambered uPVC frames, creating a hybrid system that leverages the weather resistance of uPVC with the structural strength of steel. The manufacturing process involves precise extrusion of lead-free uPVC compounds into complex cross-sectional designs featuring three to seven internal chambers, each serving specific thermal and structural functions. Within designated chambers, galvanized steel reinforcement ranging from 1.2mm to 2.0mm thickness is inserted and secured, providing the backbone that prevents warping, sagging, and dimensional instability over decades of service. The multi-chamber architecture functions as a series of thermal breaks that dramatically reduce heat transfer between interior and exterior environments. Wall thickness specifications typically range from 2.5mm to 3.0mm, ensuring adequate material density to resist impact forces while maintaining optimal thermal performance. UV stabilizers are incorporated throughout the uPVC compound during the extrusion process, protecting against solar degradation that causes discoloration and brittleness in inferior products. This comprehensive construction approach ensures Reinforced UPVC Profiles maintain their dimensional accuracy, aesthetic appearance, and functional performance even when subjected to temperature extremes ranging from -50°C to 70°C, making them suitable for diverse climate zones from arctic regions to tropical environments.

Superior Performance in Extreme Temperature Conditions

Thermal Stability and Dimensional Integrity

Extreme temperature fluctuations pose significant challenges to building envelope components, causing expansion, contraction, and eventual failure in many materials. Reinforced UPVC Profiles demonstrate exceptional dimensional stability across wide temperature ranges due to their integrated steel reinforcement system. While standard uPVC materials naturally resist thermal transfer better than aluminum or wood, the addition of galvanized steel reinforcement prevents the thermal expansion and contraction that can compromise seal integrity and operational functionality. The steel core maintains consistent frame geometry even during rapid temperature changes, ensuring that seals between glass units and frame members remain tight and effective throughout all seasons. The multi-chamber design enhances thermal performance by creating air pockets that act as insulation barriers. These chambers prevent cold bridging in winter conditions and reduce heat gain during summer months, maintaining comfortable interior environments with reduced HVAC energy consumption. Research demonstrates that properly designed Reinforced UPVC Profiles can reduce heating and cooling costs by twenty to twenty-five percent compared to traditional window systems. The profiles' natural low thermal conductivity, combined with strategic chamber placement, creates an effective thermal barrier that outperforms single-material alternatives. For buildings located in regions experiencing harsh winters with temperatures below freezing or summers with intense solar radiation, these thermal properties translate directly into energy savings, improved occupant comfort, and reduced carbon footprints.

Protection Against Extreme Cold and Heat

In extreme cold environments, Reinforced UPVC Profiles maintain operational functionality where other materials fail. The uPVC compound does not become brittle at low temperatures, unlike certain plastics that crack or shatter when subjected to freezing conditions. The integrated steel reinforcement ensures hinges, locks, and operating mechanisms continue functioning smoothly even in sub-zero temperatures. Condensation management becomes critical in cold climates, and the multi-chamber design of Reinforced UPVC Profiles helps maintain interior surface temperatures above dew point, reducing condensation formation that can lead to mold growth and frame deterioration. Conversely, in high-temperature environments, the UV-stabilized formulation prevents the degradation, warping, and discoloration that plague inferior products. The galvanized steel reinforcement maintains frame rigidity during heat expansion, preventing the operational issues that occur when frames lose their shape under thermal stress. Desert environments, tropical regions, and areas with intense solar exposure benefit particularly from these heat-resistant properties. The reflective properties of white Reinforced UPVC Profiles further reduce solar heat gain, while darker color options incorporate additional UV stabilizers to maintain color fastness and structural properties despite prolonged sun exposure. This comprehensive approach to temperature extremes ensures that Reinforced UPVC Profiles deliver consistent performance regardless of climate conditions, providing property owners with reliable building envelope components that function optimally year-round.

Weather Resistance and Impact Protection

Wind Load Capacity and Storm Resistance

High wind events including hurricanes, typhoons, and severe thunderstorms generate tremendous forces that can compromise building envelope integrity. Reinforced UPVC Profiles are engineered specifically to withstand these extreme wind loads through their steel-reinforced construction. The galvanized steel reinforcement provides the structural backbone necessary to resist deflection and deformation when subjected to wind pressures that would cause standard profiles to flex, leak, or fail completely. Advanced engineering calculations determine appropriate reinforcement thickness based on window dimensions, glass weight, and local wind load requirements, ensuring each installation meets or exceeds building code specifications for its specific location. The fusion-welded corner joints of Reinforced UPVC Profiles create monolithic frames that distribute wind loads evenly across the entire structure rather than concentrating stress at mechanical fastener points. This welded construction eliminates the weak points inherent in mechanically joined frames, providing superior resistance to racking forces that occur during storm events. Multi-point locking systems integrated with Reinforced UPVC Profiles further enhance wind resistance by securing sash members at multiple locations along the frame perimeter, preventing the flexing and separation that can occur with single-point locks. Properties in coastal regions, high-rise buildings, and areas prone to severe weather benefit enormously from these wind-resistant properties, as the profiles maintain their weathertight seal even under hurricane-force conditions exceeding two hundred fifty kilometers per hour.

Impact Resistance and Debris Protection

During severe weather events, windborne debris poses significant threats to building envelope integrity. Reinforced UPVC Profiles demonstrate superior impact resistance compared to aluminum frames or standard uPVC systems without reinforcement. The steel core absorbs and distributes impact energy across the frame structure, preventing localized damage that could compromise the entire unit. This impact resistance proves invaluable during hailstorms, where large hailstones can shatter glass and damage frames, or during windstorms that propel branches, roofing materials, and other debris against windows and doors. The inherent toughness of the uPVC compound itself contributes to impact resistance, as the material flexes slightly under impact rather than denting permanently like aluminum or cracking like brittle plastics. Combined with appropriate glazing options such as laminated or tempered glass, Reinforced UPVC Profiles create a comprehensive protective barrier against impact damage. Security considerations also benefit from this impact resistance, as the reinforced frames resist forced entry attempts that might compromise weaker systems. The combination of structural strength, material toughness, and secure locking mechanisms makes Reinforced UPVC Profiles an excellent choice for areas prone to severe weather, providing occupants with enhanced safety and property protection during extreme events while maintaining aesthetic appeal and operational convenience.

Water Infiltration Prevention and Moisture Management

Effective water management separates premium building envelope systems from inferior alternatives, particularly in regions experiencing heavy rainfall, driving rain, or prolonged wet seasons. Reinforced UPVC Profiles incorporate multiple design features that prevent water infiltration while managing moisture that does enter the system. The multi-chamber design includes dedicated drainage chambers that collect condensation and infiltrated water, channeling it safely to the exterior through precisely positioned weep holes. This engineered drainage approach prevents water accumulation within the frame cavities that could lead to corrosion, mold growth, or structural degradation over time. Weather sealing systems integrated with Reinforced UPVC Profiles typically include multiple seal lines that create successive barriers against water penetration. Primary seals prevent bulk water entry, while secondary seals capture any moisture that bypasses the first line of defense. The dimensional stability provided by steel reinforcement ensures these seals maintain proper compression and contact with adjacent surfaces throughout the profiles' service life, preventing the gaps and misalignments that occur when frames warp or sag. Sloped sill designs with gradient arrangements ensure rainwater flows outward rather than accumulating in track systems, addressing a common failure mode in poorly designed window and door systems.

The corrosion resistance of both the galvanized steel reinforcement and the uPVC material itself ensures long-term performance even in high-humidity environments or coastal locations where salt-laden moisture accelerates deterioration in other materials. Unlike wood that rots when exposed to moisture or standard steel that rusts, Reinforced UPVC Profiles maintain their structural integrity and appearance despite continuous exposure to wet conditions. This comprehensive moisture management approach protects not only the window and door systems themselves but also surrounding wall assemblies from water damage that can compromise building structure and create unhealthy indoor environments. Property owners in rainy climates or coastal regions benefit particularly from these water-resistant properties, experiencing fewer maintenance issues and longer product lifespans compared to alternative materials.

Energy Efficiency and Long-Term Cost Benefits

The thermal performance advantages of Reinforced UPVC Profiles translate directly into substantial energy cost savings over the lifetime of the building. The multi-chamber design creates effective thermal barriers that minimize heat transfer between conditioned interior spaces and external environments, reducing the workload on heating and cooling systems throughout the year. In winter months, the insulating properties prevent heated air from escaping through window and door assemblies, while during summer, they block external heat from penetrating interior spaces. This bidirectional thermal protection maintains comfortable indoor temperatures with significantly reduced energy consumption compared to single-pane systems or thermally inefficient frame materials. The low thermal conductivity of uPVC material, combined with strategic chamber placement within Reinforced UPVC Profiles, achieves thermal performance levels previously attainable only through expensive thermal break aluminum systems or triple-glazed wooden frames. When paired with modern insulated glass units featuring low-emissivity coatings and inert gas fills, Reinforced UPVC Profiles create building envelope assemblies that meet or exceed the most stringent energy codes and green building standards. Property owners recover their initial investment through reduced utility bills within several years, while enjoying improved indoor comfort and reduced environmental impact throughout the profiles' multi-decade service life.

Beyond direct energy savings, Reinforced UPVC Profiles contribute to long-term cost benefits through their minimal maintenance requirements and exceptional durability. Unlike wooden frames requiring periodic painting, sealing, and repair, or aluminum systems that corrode in certain environments, Reinforced UPVC Profiles maintain their appearance and functionality with only occasional cleaning using mild soap and water. The UV-resistant formulation prevents the fading and chalking that necessitates refinishing in other materials, while the corrosion-resistant construction eliminates the replacement costs associated with rust-damaged components. The profiles' resistance to warping, swelling, and dimensional changes ensures operational hardware continues functioning properly without the adjustments and replacements required when frames lose their original geometry. These reduced maintenance requirements and extended service life make Reinforced UPVC Profiles an economically superior choice for residential, commercial, and institutional applications, delivering value that extends far beyond the initial purchase price.

Conclusion

Reinforced UPVC Profiles deliver unmatched protection and performance in extreme weather conditions through their steel-reinforced construction, multi-chamber design, and engineered weather resistance. These advanced profiles protect buildings from temperature extremes, severe storms, water infiltration, and impact damage while providing superior energy efficiency and minimal maintenance requirements throughout decades of reliable service.

Cooperate With Hunan Haolv Building Materials Co., Ltd.

Haolv Building Materials Co., Ltd. brings over eighteen years of manufacturing expertise in producing premium Reinforced UPVC Profiles that meet international quality standards including GB/T 8814-2017 and ISO 9001 certification. Our state-of-the-art production facility features advanced extrusion lines, precision CNC cutting equipment, and automated assembly systems that ensure consistent quality across every profile we manufacture. As a trusted China Reinforced UPVC Profiles factory, China Reinforced UPVC Profiles supplier, and China Reinforced UPVC Profiles manufacturer, we offer wholesale Reinforced UPVC Profiles with competitive pricing, comprehensive Reinforced UPVC Profiles quotation services, and Bulk Reinforced UPVC Profiles orders with flexible delivery schedules. Our Reinforced UPVC Profiles price and Reinforced UPVC Profiles Pricelist accommodate various project budgets, while our Customized Reinforced UPVC Profiles services address unique architectural requirements and performance specifications. We provide one-stop product support from profile selection through installation guidance, free technical consultation and solution design services, free sample shipping service, and full-process project follow-up to ensure your complete satisfaction. Contact us today at kristin@haolvwindows.com to discuss your requirements and experience the quality difference that comes from partnering with a dedicated manufacturer committed to excellence in every profile we produce.

References

1. Weather Resistance and Durability of uPVC Window Systems in Extreme Climates - Building Research Institute, Journal of Construction Materials

2. Thermal Performance Analysis of Multi-Chamber uPVC Profiles Under Temperature Variations - International Institute of Energy Efficiency Studies

3. Structural Performance of Steel-Reinforced uPVC Frames in High Wind Load Conditions - Association of Structural Engineering, Technical Report Series

4. Comparative Study of Building Envelope Materials: Longevity and Maintenance in Diverse Weather Conditions - National Building Standards Organization

5. Impact Resistance and Weather Sealing Properties of Modern uPVC Window and Door Systems - Materials Science and Engineering Research Council